Small businesses lagging behind in automation

Robots are still too expensive and troublesome for small businesses, but a new research project at the University of Southern Denmark is about to change all that.

Although robots have long since taken over tedious work at large factories, small and medium sized businesses are lagging behind in automation. A research projecet at the University of Southern Denmark will now make robots so cheap and easy to use that small businesses will also buy them.

- Our goal is to develop robots that are so flexible and easy to operate that businesses with small productions can see the advantage of automating production instead of moving it out of the country, for example to China, says Professor Norbert Krüger from the Maersk Mc-Kinney Moller Institute at the University of Southern Denmark.

The robot mimics movements

The project is called ReconCell and is a large EU project which will equip European businesses for global competition. The researchers will make sure that the robots are easy to programme so they can quickly adapt to new tasks. The robots will also be safe to use and deliver flawless work.

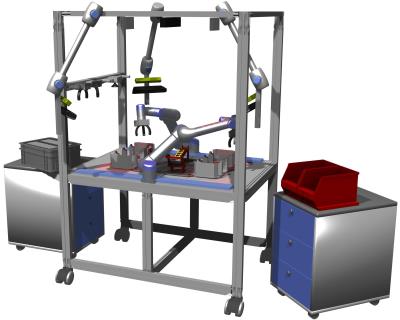

To this end researchers have come up with a design that resembles a robot cage from which 2 robot arms work with what they can see using their 3D vision system. The robot uses its vision to find and pick up items that come into the cage. Depending on what the robot's computer is programmed to do, the robot can then assemble the parts.

- The devil is in the detail and our challenge is both how to design the robot's fingers so they can safely handle small parts, but also to get all the technologies to work together so that businesses get a robot that is safe to use and easy to programme, says Norbert Krüger.

Robot collects lights

In the development of the future's flexible robot-worker researchers have visited many small and medium sized businesses and they are helping to develop a robot solution for a company that assembles car lights.

- The company employs 8 people to assemble the lights. It is expensive and a classic example of a production where it would be advantageous for a robot to take over the routine work so that the business isn't forced to close down but is instead equipped for global competition, says Norbert Krüger.

The researchers are about to visit even more businesses to find collaboration partners who can see the benefits in automating their production. The researchers have carried out a very precise business analysis that shows that if a business produces more than ?1000 items, investing in a ReconCell robot would result in financial gain.