Løbende ph.d. projekter

Beskrivelse

The electrification of systems, driven by advances in battery technology, stands at the forefront of modern energy transformation. This Ph.D. dives into the benefits, boundaries, and limits of system electrification, with a particular focus on the important role of battery technology and the integration of artificial intelligence (AI). As the demand for efficient and sustainable energy solutions intensifies, batteries emerge as crucial components, powering everything from electric vehicles to renewable energy storage systems.

The enhancement of battery performance and lifecycle through AI is core to this Ph.D. AI algorithms enable precise estimation of state-of-charge (SOC) and state-of-health (SOH), essential for optimizing battery usage and ensuring reliability. Furthermore, AI-driven fault detection mechanisms significantly mitigate risks, enhancing safety and reducing maintenance costs.

This work also explores the potential of second-life batteries, repurposing used batteries from electric vehicles for renewable energy storage and grid stabilization. This not only extends the lifecycle of batteries but also addresses sustainability concerns by reducing waste.

While the benefits of system electrification are substantial, this study also acknowledges the boundaries and limits inherent in current technology and infrastructure. By understanding these constraints, we can better navigate the path towards a more electrified and sustainable future.

This project is supervised by Assoc. Professor Kasper Paasch.

Contact information: Ph.D. student Henrik Andersen - email: han@sdu.dk.

Beskrivelse

The vision for a more sustainable future premisses the exploitation of renewable energy, projected to increase by 20% worldwide in the next 25 years. This is only achievable with the improvement of the employed power electronics from a reliability standpoint. More specifically it is important to exceed the failure rate in parts per million level of power electronic devices to meet the future applications standards. The performance of modern power electronic systems is limited by the wear-out mechanisms of the converters, which are a source of failure according to industrial records. The converters' expected lifetime deterioration is initiated by operating and climate conditions, such as power loading, ambient temperature, and humidity. Across the harsh environment application profiles, the most affected components after semiconductors are the metallized polymer film capacitors (MPFCs), in which the survey participants hoped for a more extended research focus.

In the realm of green energy technologies, there is a pressing demand for capacitors to operate under elevated electric fields and ambient temperatures. As technological advancements are under the heel of higher investments, the supremacy of BOPP remains evident. Even though it meets the current market demands as a reliable performance and cost-effective polymer film, still suffers from low thermal and dielectric properties. Additionally, the trend towards thinner dielectric films to meet miniaturization requirements poses challenges to maintaining optimal dielectric properties, microstructure morphology, and surface conditions. Manufacturing processes induce physical and chemical defects impacting overall capacitor reliability and performance. Especially in power electronics where metallized polypropylene film capacitors (MPPFs) are widely employed, the thinning of the dielectric foil downgrades the advantage of high breakdown strength, which under high temperatures increases the susceptibility to accelerated degradation.

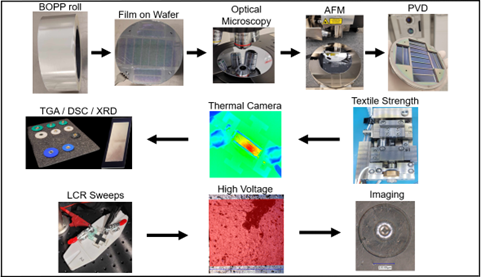

Biaxially oriented polypropylene thin films, known for their low energy loss, high breakdown strength, and excellent self-healing capability, are key dielectric materials used in state-of-the-art capacitors. The scope of this project is the optimization of MPPFs through techniques that aim at a slower initiation of the injection mechanisms occurring under an applied electric field, which impedes current leakage generation and decreases joule heating. The strategies employed towards the amelioration effort of MPPFCs involve material modification and multilayer engineering. The fabrication and characterization processes are conducted entirely in-house, as depicted in the figure above. The equipment utilized includes a Cryofox 600 Explorer physical vapor deposition system, a TA DSC 25 differential scanning calorimeter, an optical microscope Keyence Digital microscope VH-ZST, a Veevo Dimension 3100 atomic force microscope, a D8 Advance x-ray diffraction system, a Keysight E4980AL Precision LCR meter, and a Vitrek 951i Series Hipot tester, among other metrology instruments.

This project is supervised by Assoc. Professor Luciana Tavares.

Contact information: Ph.D. student Odysseas Gkionis-Konstantatos - email: gkionis@sdu.dk.

Beskrivelse

This PhD project aims to delve deeper into the internal workings of AlElCaps by developing a simulation that considers both physical and chemical behaviors. The primary challenge will be to simulate various parameters such as foil thickness, etching properties, paper layers, and the chemical behavior of the electrolyte. Additionally, the simulation will estimate Equivalent Series Resistance (ESR) values and other critical properties of AlElCaps. Additionally these parameters will be used to reduce parasitics and build new Electrolytic Capacitors.

This project is supervised by Professor Thomas Ebel.

Contact information: Ph.D. student Jonas Wittmaack - email: wittmaack@sdu.dk.

Beskrivelse

Capacitors are a major component of any electrical circuit. There are different capacitor technologies with different characteristics and depending on the specific use, a suitable technology is chosen. In power electronics, an important use is as a DC link capacitor.

One type of capacitor technology is the aluminum liquid electrolyte capacitor. Due to a high surface area of the dielectric, a very high capacitance per volume can be achieved. The dielectric is an aluminum oxide, which can be grown directly on the aluminum. To achieve an electrical connection to the dielectric, a liquid electrolyte is necessary. Poor conductivity values and evaporation of the electrolyte lead to high series resistances and reduced lifetime values. A semi-solid conducting polymer can exchange the liquid electrolyte, greatly improving the mentioned problems. However, such devices are only available with rated voltages up to 200 V. That means it cannot be used in many power electronic applications, as higher voltages are usually necessary.

An important application would be in automotive power trains, where voltages are around 450 V today with trends going towards 800 V and higher. Having the high capacitance per volume of electrolytic capacitors with low series resistance values and increased lifetime could greatly improve the efficiency and power density of the power train and other applications.

The goal of this PhD project is thus to develop a polymer aluminum electrolytic capacitor with a rated voltage of up to 1000 V. To do this, a process must be developed to grow a reliable and thick aluminum oxide on pure aluminum. This will be achieved by investigating the influence of process parameters on the oxide through different techniques including but not limited to SEM, FEM, and XRD. Once a repeatable process is established, a method to increase the surface area and thus the capacitance will be developed. Lastly measures to increase lifetime and reliability are researched.

This project is supervised by Professor Thomas Ebel and Assoc. Professor Luciana Tavares.

Contact information: Ph.D. student Tim Kruse – email: timkruse@sdu.dk

Tidligere ph.d.-projekter

Beskrivelse

This PhD thesis contributes to modeling and optimizing electric vehicle (EV) charging at different scales. Local-scale EV charging simulations address the concern about the local grid, where the optimization objective is to flatten the overall charging load, and the concern from EV users, where the objective is to ensure a fair share of the supply energy and maximize the delivered energy to the EVs. Large- and urban-scale EV charging simulations focus on the synergy between EV load and renewable energy sources (RESs). The investigations were carried out in five studies.

At a local EV charging network, the first study found that with a small percentage of EV charging stations being uncontrollable, smart EV charging can still achieve good performance. Besides, simply utilizing the mean value of historical data to predict the charging behavior of the future arriving EVs can significantly improve the scheduling performance. The second study found that, in a limited supply charging network, the improvement in energy delivery amount is insignificant by considering state-of-charge-dependent maximum charging power.

For a large- or urban-scale energy system, the third study showed that the computation time was reduced significantly by simply aggregating the charging power and energy content. However, this simple model overestimates the energy system performance. On the other hand, the overestimation tends to converge when considering more and more EVs, and the values are small. Thus, the fourth study applied the simple aggregated model for urban-scale energy system evaluation. The result shows that, compared to smart charging, allowing vehicle-to-gird can achieve optimal energy system performance in a RES-powered net-zero energy city. Otherwise, net-zero leads to over-sized RES generation.

The fifth study validated a two-stage approach for large-scale EV charging with on-site photovoltaic (PV) generation, where the first stage approximates the overall charging load and the second prioritizes charging. The simulation results showed that the aggregated model can accurately approximate the load, and different sorting-based methods perform slightly differently when prioritizing charging but with other distinct behaviors.

In conclusion, the thesis shows the modeling and optimization of EV charging at different scales and the potential of smart EV charging in addressing different concerns regarding transportation electrification.

This project is supervised by Professor Thomas Ebel.

Contact information: Postdoc Kun Qian– email: kqian@sdu.dk.