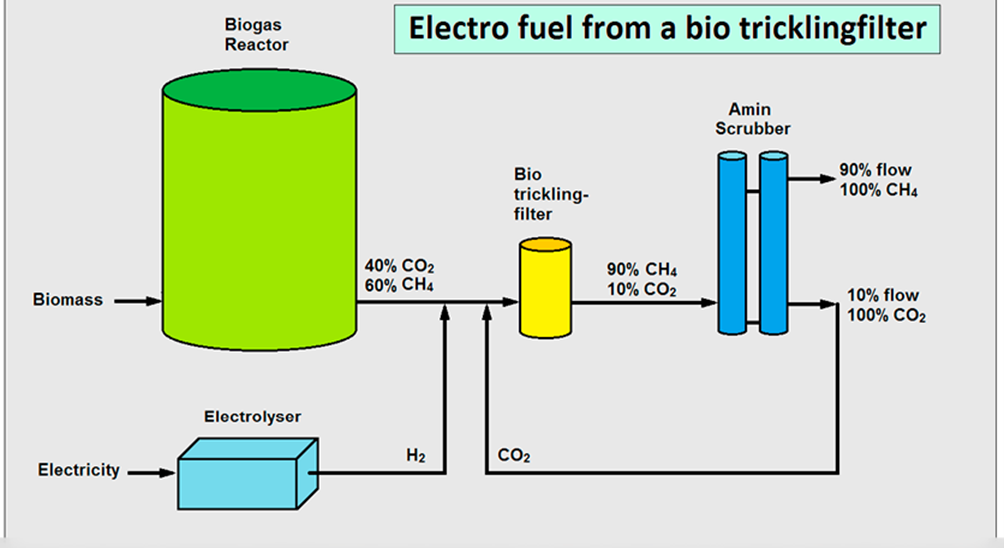

Through this project we develop biologically mediated upgrading systems from lab-scale to industry scale, where H2 generated through water electrolysis is biologically converted to CH4 by the action of autochthonous hydrogenotrophic methanogens.

The specific tasks in the project are:

- Standardize the design of bio-trickling filter reactors for ex-situ methanation

- Maximize the production capacity of CH4 per unit volume of the reactor

- Tests of different packing materials

- Develop SOP for the startup and operation of the bio-trickling filter reactors

- Direct inoculation with digestate from biogas plant

- Nutrient consumption and dosing strategy

- Nutrient trickling strategy

- Cooling of full-scale plants

- Recirculation of the product gas

- Design and test the operation of a 2 m3 pilot plant.

Group members:

- Professor, head of department Jens Ejbye Schmidt

- Professor, Henrik Wenzel

- Assistant professor, Muhammad Tahir Ashraf

- Executive officer, Lars Yde

Selected publications

- Optimizing the dosing and trickling of nutrient media for thermophilic biomethanation in a biotrickling filter. 2021. Ashraf, M. T., Yde, L., Triolo, J. M., Wenzel, H., Biochemical Engineering Journal, 176, 108220.

- Direct inoculation of a biotrickling filter for hydrogenotrophic methanogenesis. 2020. Jønson, B. D., Sieborg, M. U., Ashraf, M. T., Yde, L., Shin, J., Shin, S. G. & Triolo, J. M., 2020. Bioresource Technology. 318, 1- 8.

- Biomethanation in a thermophilic biotrickling filter — pH control and lessons from long-term operation. 2020.Ashraf, M. T., Sieborg, M. U., Yde, L., Rhee, C., Shin, S. G. & Triolo, J. M. Bioresource Technology Reports. 11, 100525.

- Biomethanation in a thermophilic biotrickling filter using cattle manure as nutrient media. 2020. Sieborg, M. U., Jønson, B. D., Ashraf, M. T., Yde, L. & Triolo, J. M. Bioresource Technology Reports. 9, 100391.