SDU Robotics Implements Technology on a Highly Flexible Assembly Robot at Danfoss

Together with our partners in the national SPIR project MADE – a platform for future production - and the national project Carmen, SDU Robotics has developed technologies for a highly modular, reconfigurable and mobile assembly platform running production at the Danfoss facilities in Silkeborg.

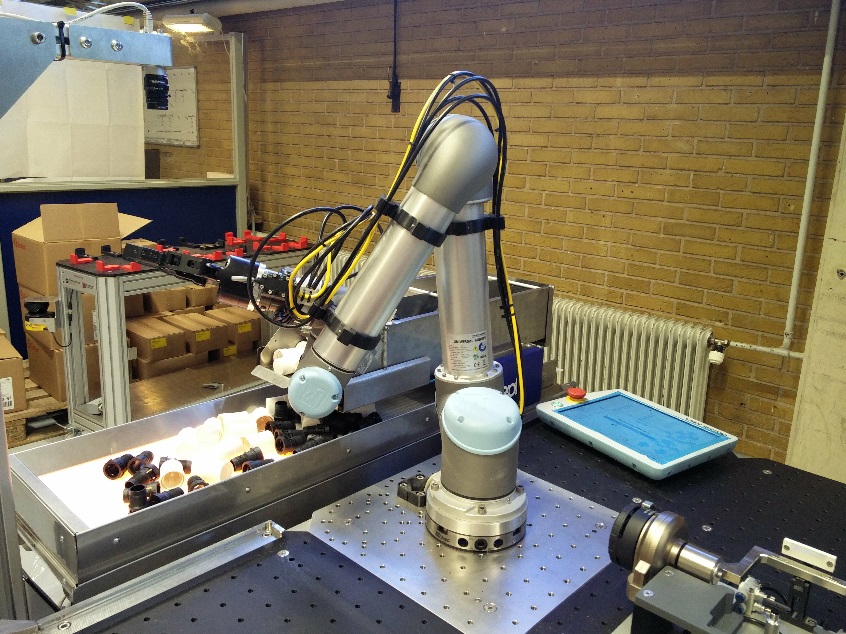

The idea with the platform concept is that when it has finished one task, it can be quickly reconfigured by interchanging the 40x40 cm tiles (see picture) and roll out/in a number of dock-in tables with peripheral equipment. Changeover time can be less than 10 minutes. With this technology, it can therefore become feasible to automate tasks where manufacturing tasks running only a few hours per day can become economically feasible to automate. Currently, the platform are only used in two different configurations, but in the future we will work with concepts with a much larger variety of tasks that can be handled by the same platform.