Microbes Feed on Iron: New Study Reveals How They Do It

Corroding microbes are a costly menace for industries relying on hidden and underground iron structures like sprinklers and oil pipelines. A recent study by researchers from the University of Southern Denmark sheds light on the mechanisms behind microbial-induced corrosion (MIC), offering insights that could help prevent damage.

Pipelines, sprinklers, and other infrastructure in oxygen-free environments are vulnerable to Microbially Induced Corrosion (MIC)—a process where microorganisms degrade iron-based structures, potentially leading to costly damages or even collapses.

Unlike rust, which is caused by a chemical reaction with oxygen, MIC occurs in oxygen-free environments. The microbes responsible thrive on the iron itself, producing a destructive reaction that damages the material. This kind of corrosion costs industries billions of dollars annually, particularly in sectors like oil and gas. Identifying and preventing the microbial activity behind the corrosion is therefore of importance.

Now, microbiologists, PhD. Satoshi Kawaichi and Professor, Dr. Amelia-Elena Rotaru from University of Southern Denmark have uncovered new details about how one microbial strain of the species Methanococcus maripaludis corrode iron in an extremely efficient way. The study was funded by a Sapere Aude grant awarded to Amelia-Elena Rotaru by the Danish Independent Research Fund. It is published in npj Biofilms and Microbiomes.

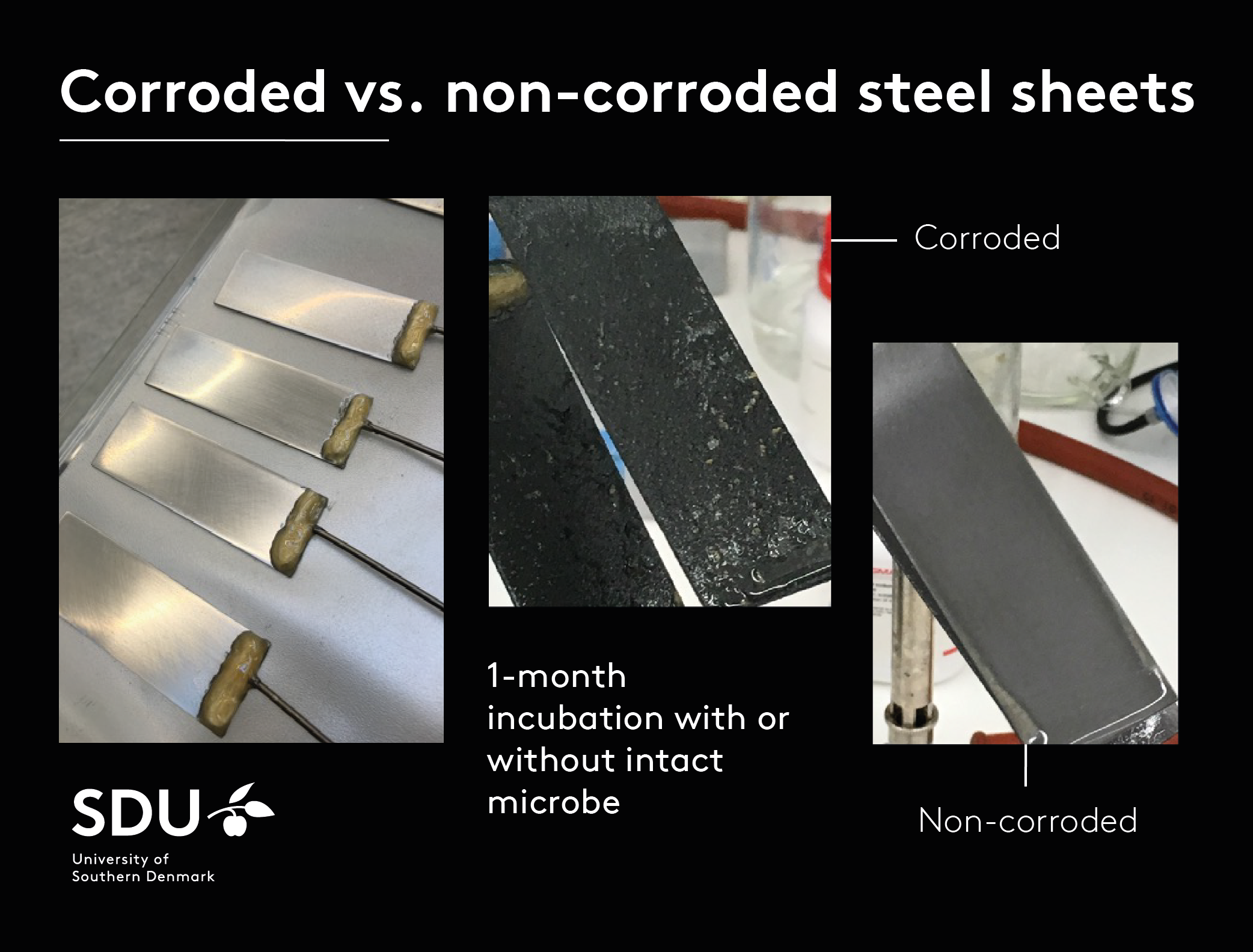

The study refutes the long-standing belief that these microbes release enzymes into the environment to corrode iron and have them produce nutrients for the microbe’s growth. Instead, the researchers show that the microbes cling directly to the iron surface, using sticky enzymes on their cell walls to extract what they need without wasting energy on releasing enzymes that may not reach the iron surface.

Once attached to the iron surface, the microbe initiate corrosion developing quickly a black film on the material surface.

- The microbes will quickly create pits under this black film, and within a few months, significant damage will occur. I would say that 5-gram iron granules visible with the naked eye are bio-deteriorated to a black powder in a month or two, said Satoshi Kawaichi.

Also an environmental burden

According to the researchers, microbial adaptation like this is an example of how microbes can learn to thrive in human-made environments. In this case, Methanococcus maripaludis, has learned to survive on and efficiently get energy from iron structures.

Such microbial adaptation poses not only a financial burden but also an environmental one:

- These microbes are methanogenic, meaning they produce methane. Methane is a potent greenhouse gas, so it does cause some concern that microbes adapting to human-made, built environments produce methane more effectively. These new adaptations may spur increases in methane emissions, said Amelia-Elena Rotaru.

Microbes produce methane

Methane producing microbes also thrive on a variety of mineral particles, that are being released to the natural environment by climate change and other anthropogenic activities. Such particles come from industry, agriculture, forest fires, river runoffs, melting glaciers, etc. and they may promote the activity of certain methane-producing microbes.

Currently, members of Rotaru’s research group are investigating glacier melt particles from Greenland to see how the particles influence methane emissions to the atmosphere.

Amelia-Elena Rotaru is the holder of a European Research Council Consolidator Grant with the project title “Conductive Minerals as Electrical Conduits in Methane Cycling”, and of a Novo Nordisk Ascending Investigator looking at how certain methanogens can convert CO2 and electricity to methane. Read more about it here.

Meet the researcher

Amelia-Elena Rotaru is Professor and Head of Research at Department of Biology. Her research is funded by the Independent Research Fund Denmark, the Novo Nordisk Foundation and a European Research Council Consolidator Grant.