Danish robot researchers win prestigious competition

Researchers from the Maersk Mc-Kinney Moller Institute at SDU have won first prize in a competition at the international IROS conference. Their solution demonstrates that flexible objects, such as wires, can now be routed and adjusted using robots. This opens for new industry uses for robots.

Those who work with robots, know what IROS means: The four letters refer to the world's leading academic robot conference, where thousands of researchers from all over the world meet annually.

About IROS

- IROS stands for International Conference on Intelligent Robots and Systems,Here, researchers meet to discuss perspectives within robot technology at the absolute top level

- The conference has been held annually since 1988 and has previously been held in cities such as Tokyo, Vancouver, Las Vegas and Madrid

- Due to Covid-19, it took place online in 2020, so the SDU team won the competition from the Industry 4.0 Lab in the basement of the Faculty of Engineering, where a large number of cameras helped to document their solution

- SDU Robotics was selected as the winner of the competition on 6 November 2020

The conference includes a robotic assembly competition, and this year it was won by SDU Robotics, which is part of the Maersk Mc-Kinney Moller Institute at SDU.

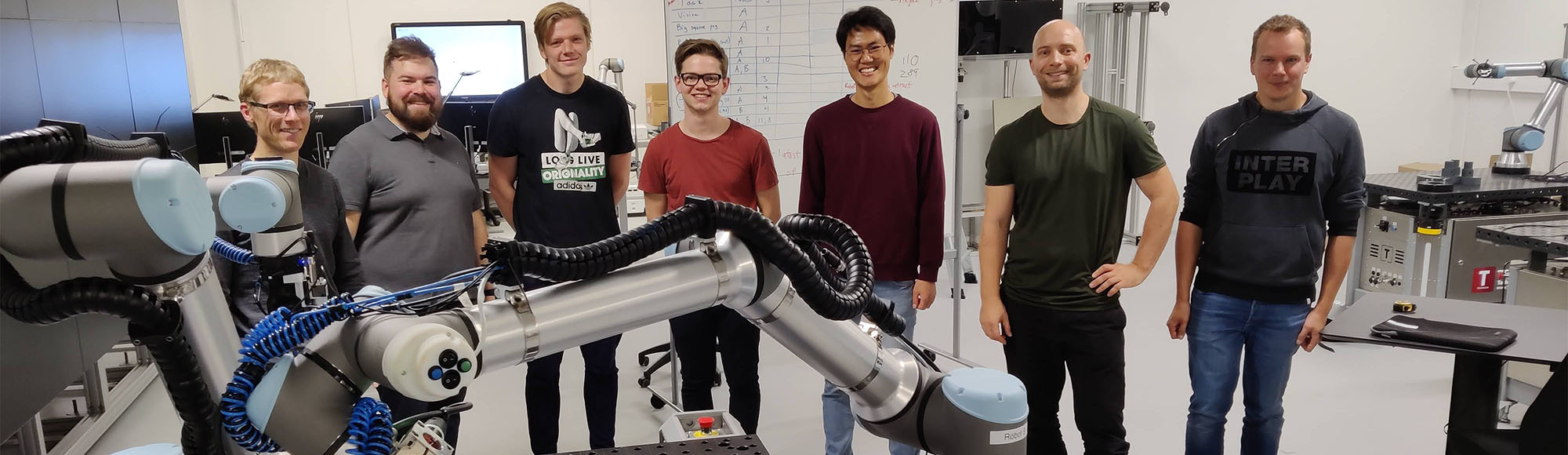

The victory gives recognition in both scientific and industrial environments, and it opens the doors to new ways of using robots, says associate professor Christoffer Sloth, who coordinated the seven-man SDU team during the competition.

– IROS is known throughout the international robotics research community, and this competition is known to be very tough.

– We are pleased that we managed to demonstrate that robots can not only mount fixed parts such as screws and plastic lids but also flexible parts such as cables and straps, because this ability can be used in many contexts in the future, he explains.

New types of assembly tasks

The competition brief was to enable robots to solve new types of automatic assembly tasks relevant to the industry. Among other things, the team had to get the robot to mount screws, cables and straps on a mock-up board, and that was a big challenge, especially when it came to the manipulation of flexible parts.

The SDU team spent a month on the preparations, spending both days and nights in the laboratory. Their efforts resulted in the highest number of points ever given in the competition, as well as a time bonus.

– In fact, our solution is a further development of a setup we used, when we won the WRS competition in Japan in 2018, says associate professor Anders Glent Buch from SDU Robotics.

”The SDU team's solution is robust and streamlined. They have been working for a long time to develop a flexible workstation for automated assembly tasks that can be used commercially.

– We chose to use two robots, one equipped with a camera and the other with a programmable screwdriver. Both robots have a parallel gripper fitted, and then we ensure that they work together to solve the complex problems.

The solution impresses Joseph A. Falco of the National Institute of Standards and Technology, who co-organized the competition.

– The SDU team's solution is robust and streamlined. They have been working for a long time to develop a flexible workstation for automated assembly tasks that can be used commercially. It is also clear that they know how important it is to approach the challenge from many different perspectives at the same time, he praises.

World-class research

The victory helps to strengthen the strong position that SDU has on the international stage, and that pleases Henrik Bindslev, the dean of the Faculty of Engineering.

– The result of the competition shows that SDU Robotics is at the highest international level within control of industrial robots. The tasks the team has solved are extremely complex, he says.

– With great creativity, based on a deep understanding of the topic, the team has demonstrated that cooperating robots can now solve difficult tasks of assembling and, not least, disassembling devices. These are tasks that today depend on dexterous labour.

New opportunities for recycling

The perspective is that people can be released from enervating and exhausting workflows. The perspective is also that the world can, to a greater extent, dismantle used appliances for the purpose of recycling materials rather than throwing used appliances in landfills, he explains.

– It attracts attention that we, now for the second time in two years, win an international competition among the world’s best, and this opens up further opportunities. We will of course seize these opportunities, so that we will also be at the forefront of robotics in the future, states Henrik Bindslev.

Photo: Maersk Mc-Kinney Moller Institute.

About the competition

- The official name of the competition is "2020 IROS Robotic Grasping and Manipulation Competition"

- Participants were given two hours to solve a task, which consisted of two main themes: disassembly and assembly. The task was to be performed on a NIST Task Board, which is a board of 40 by 40 centimeters

- SDU Robotics used a dual-robot set-up with a camera for locating the board, a programmable screwdriver, parallel grippers, interchangeable "fingers", and coordinated dual-robot movements for handover and for the solution of mounting rubber bands and cables

- It is the first time in the history of the competition that a team has achieved the maximum number of points and, on top of that, has been awarded a time bonus