Despite being, after water, the most widely used material in the world with a yearly usage of more than 2 billion tons, no fully efficient solution has yet been developed for the production of complex concrete constructions. State-of-the-art research demonstrates the potential of using Additive Manufacturing (AM) in the realm of architecture and construction as it carries a series of inherent advantages in design, material use and economic sustainability. Employed for the production of formworks, Additive Formwork (AF), or to directly shape the material, 3D Concrete Printing (3DCP), exists applications of AM in the production of concrete elements. However, there is a lack of consolidated workflows of design, analysis, and production that offer a competitive advantage against other technologies yet being economically and environmentally sustainable.

How AM can impact the design and manufacturing of concrete construction? Which design paradigms is this technology unfolding? How can we improve the efficiency of concrete construction by combining performance-based design and AM?

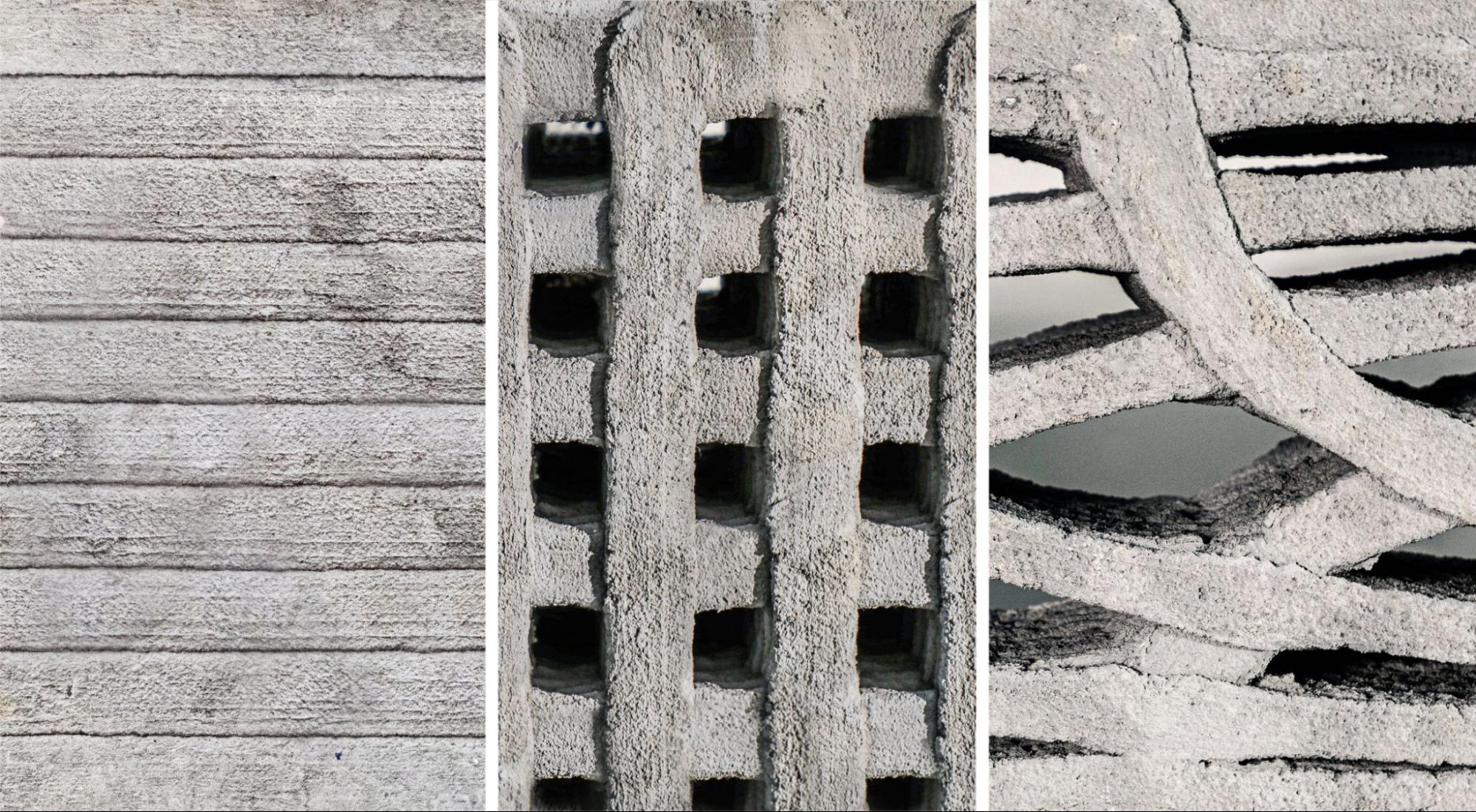

With the scope of developing design optimization routines and fabrication planning informed by performance analysis as well as manufacturing constraints, the work carries out an incremental series of experiments as testing and data-gathering platforms. Using a research-by-design methodology, and with a focus on 3D Concrete Printing (3DCP) technology, the PhD project investigates the interdependencies between geometry, digital fabrication and material performance with the goal of outlining fabrication-aware design workflows that can unfold new aesthetic and performative design solutions in the concrete AEC.