We perform state-of-the-art research in technology entrepreneurship and innovation leading to smart products, business and factory of the future

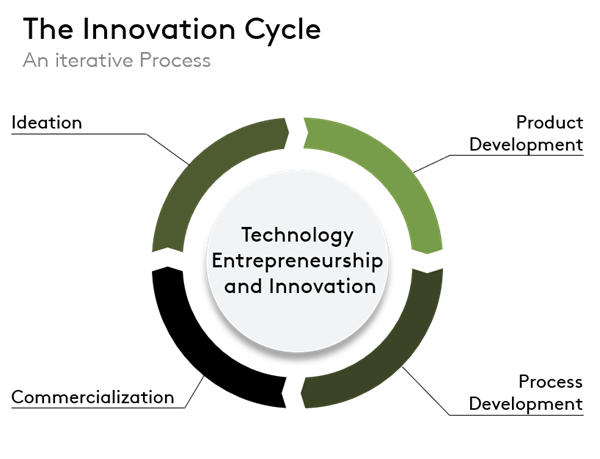

The TEI section’s research considers various phases of the innovation process, and it extends the traditional view by considering the boundary-crossing and interdisciplinary nature of innovation from Engineering to Business. Starting from ideation to developing a first prototype, setting up manufacturing enabling and applying technologies of the Industry 4.0, up to commercialization on the market. The focus is general engineering and how to generate innovate products and production of the future.

The focus is to develop and demonstrate technical engineering solutions in combination with comprehensive business models.

This is done by bringing together engineers and innovative business researchers who in collaboration can transform an idea into a tangible innovation, that may become a new smart product or service.

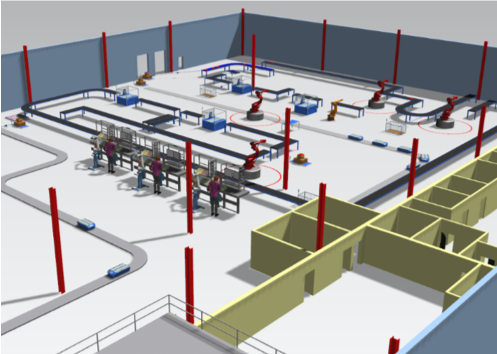

A big focus for the researchers is the Smart Factory where researchers the digitalized and automated factory of the future is designed and developed. The researchers work with virtual simulation tools where virtual prototypes and digital twins of the production can be tested in a virtual VR environment before implementation.

These joint forces represent the backbone of our education programmes on Engineering, Innovation and Business.

In collaboration with internal and external partners, the SDU TEI group is a reliable and qualified partner for the local industry in joint projects.

Related Research at the Faculty of Engineering

If you are interested in related research at the Faculty of Engineering, read more here

Sustainable Entrepreneurship and Innovation

We promote the development of sustainable entrepreneurship both within established companies and new ventures.

To sustain innovative growth in the region, we aim to (1) contribute to identify opportunities for sustainable innovation in business models of technology-based companies; (2) identify opportunities for new technology-based start-ups with a focus on sustainability within the region; (3) develop and operationalize concepts that improve university-industry collaboration within sustainable entrepreneurship and innovation.

Digitalized Sustainable Manufacturing and Supply Chains

Smart Factory - Automation and Digitalization - Industry 4.0

We build up theory and transfer knowledge about sustainable manufacturing systems with high level of automation and digitalization. Our mission is to make Industry 4.0 understandable and to challenge companies by innovative and disruptive product development, automation and digitalization for data driven solutions. The goal is to become leading in prototyping, simulation and modelling in the product life cycle, especially in plant and process modelling leading to digital twin solutions.

Research areas

-

![]()

Computer simulation

This research focuses on Product Life Cycle Management (PLM) from product prototyping to the design of production system. Through computer simulation (stochastic discrete event plus continuous models), we can model production systems and supply chains to perform experiments is the basis for detailed analyses and optimizations. Corresponding to rapid technological developments, we are constantly fostering our competences in computer simulation and data-driven models to be able to perform top-notch research.

-

![]()

Digital Twins

Our research experience in simulation and virtual reality is edging us towards digital twins. This finds application on the product level, where a virtual model allows analyses of the actual product. Even more so, a digital twin of entire production systems opens avenues for optimization analyses and is therefore guiding current research. Corresponding research questions concern the operation, collaboration and real potential of the concept of digital twins.

-

![]()

Operator 4.0

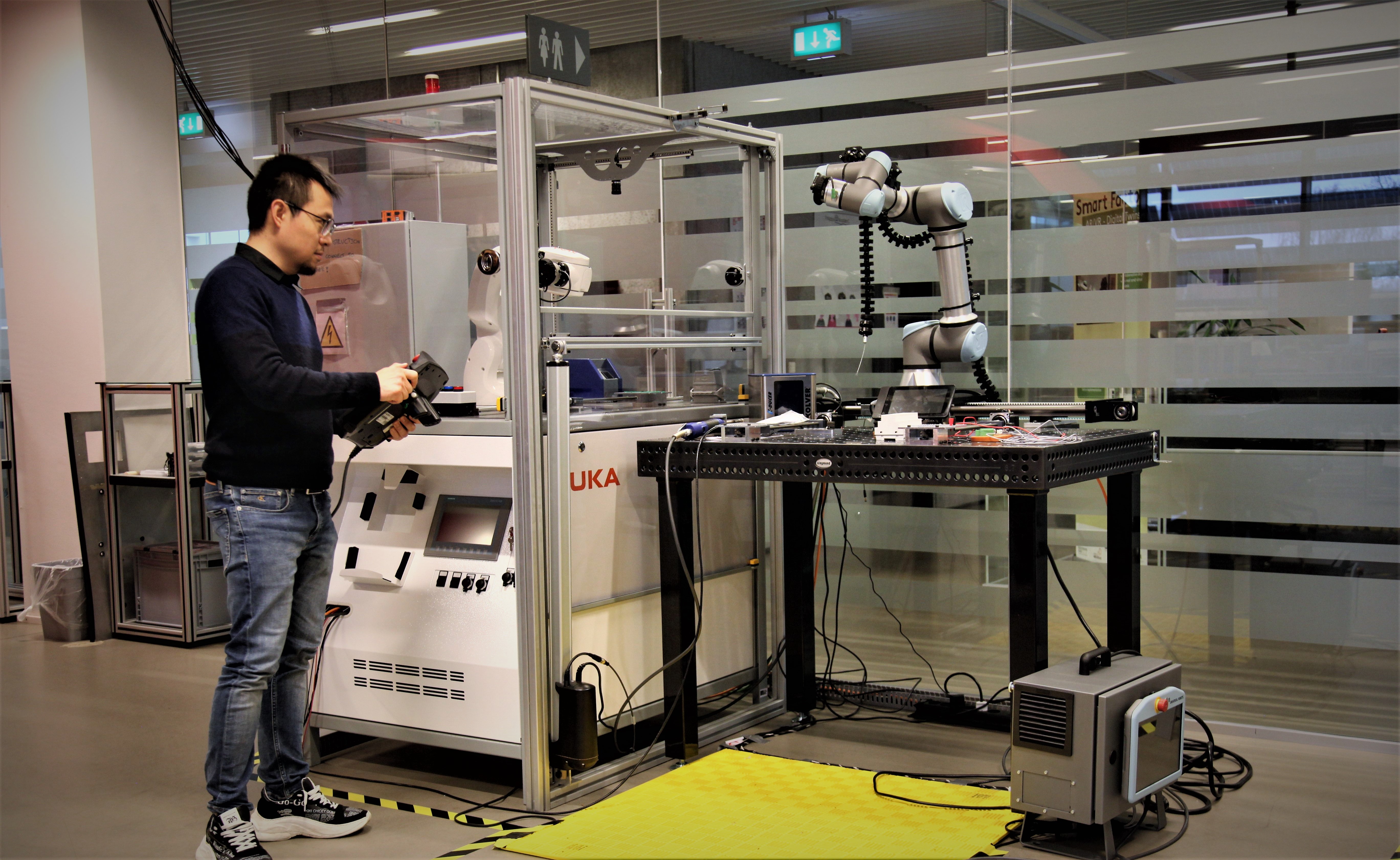

One important element of the Smart Factory research is the design of future workplaces seen from the organizational and the human perspective. Therefore, we investigate the topic Operator 4.0, where we expect the future scenario to take human cyber-physical production systems (H-CPPS) into account. This has implications for the competences and roles of future employees and the companies and industrial structure as such. Our research in this area is thus directly related to Industry 4.0 and the implementation thereof. We research HRC - Human Robot Collaboration solutions, where we use simulation and the digital twin in the design phase as well as in the operation phase.

-

![]()

Virtual and Augmented Reality

Using virtual and augmented reality, we design digital prototypes of products and the production systems. In our research, we link virtual models of production systems to simulation models, which enables a virtual “walk in” into production systems and manufacturing lines. Through adaption and remodeling of single elements or entire systems, we can then identify and utilize optimization possibilities, e.g. in the working environment with collaborative robots.

-

![]()

Innovation Lab

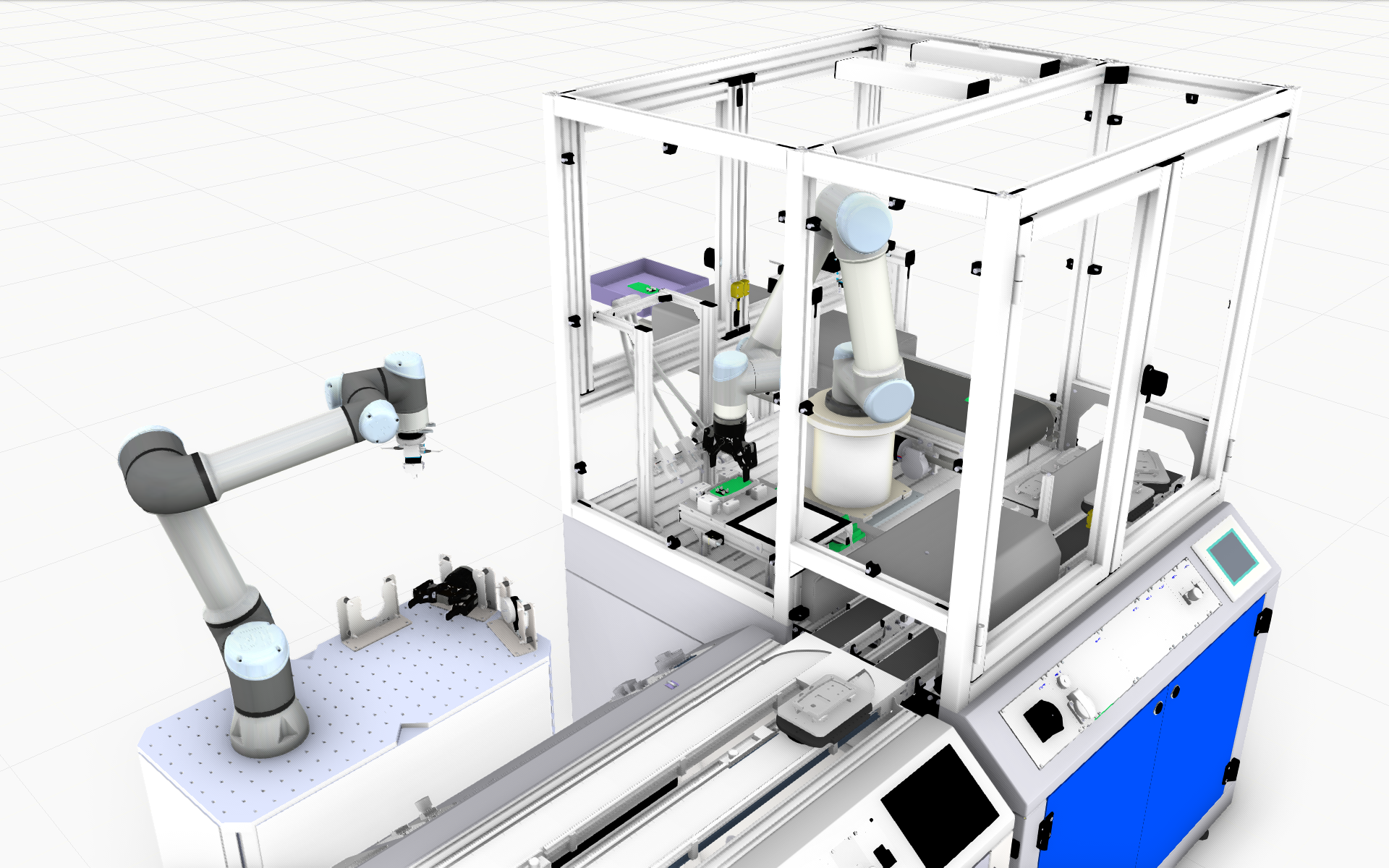

The Innovation lab is a playground and test facility for our research where we can present virtual simulations and physical small-scale production. The Innovation lab consists of the Simulation lab, the VR lab and the physical Smart Factory lab. In the Smart Factory lab we demonstrate new production concepts of the future based at modular and reconfigurable thinking. Combining virtual models and the physical systems gives new opportunities to develop and test different types of digital twins of products, production and supply chains.

We even have a virtual lab environment, where we are able to connect to other labs around the world, to research and demonstrate collaboration on the distance and in the virtual world.