Motor test lab

A state-of-the-art lab equipped with the latest measuring and testing instruments.

Description

The lab has five motor-generator load test benches with a facility to customise and couple different motor-generator sets. It is equipped with various types of electric machines and able to simulate various load conditions.

We are working in the area of energy efficient electric drive systems with advanced power converters. We can run various types of electric machines with Si-based as well as SiC-based next generation power converters. There is a possibility to run the systems with advanced all SiC-based three-level converters up to 20 kW. This is ideal for companies that would like to compare the performance of their system with Si -based and SiC based power converters.

The lab is equipped with a grid simulator and current controlled high-power DC supplies. In addition, we also have various realtime controller platforms that can be used for rapid prototyping of the system. We have experience with advanced PWM and control strategies for electric drives systems. The lab provides consultancy in the area of electric drives, control of power converters, electric machines etc.

Services for companies

In our facilities, we can perform the following tests:

- Load testing of electric machines up to 22 kW

- Load testing of power converters up to 22 kW

- Efficiency measurements of electric drive systems, electric machines and power converters up to 22 kW

- Performance evaluation of electric machines with next generation SiC based two- and three-level power converters.

Technical specification of equipment

LeCroy 12 bit oscillloscope

model 8208HD, 8 channel, 12 bit, 2GHz, 10GS/s and 50M memory/ch.

Regenerative bidirectional power supplies

- ITECH IT6012C-800-40 800 V/40 A/12 kW

- ITECH IT6018C-800-60 800 V/60 A/18 kW

Power analyser

Yokogawa precision power analyser model WT5000 with 7 channels

- AC power accuracy: 0.01% of reading + 0.02% of range

- DC power accuracy: 0.02% of reading + 0.05% of range

- 10 MS/s 18 bit ADC

Spitzenberger grid simulator

EMV D 45000/PAS: For measurements according to EN60555-2/3, EN 61000-3-2/3,EN 61000-3-11, EN 61000-3-12, EN 61000-4-8, EN61000-4-11, EN61000-4-13, EN61000-4-14, EN61000-4-17, EN61000-4-27, EN61000-4-28, EN61000-4-29

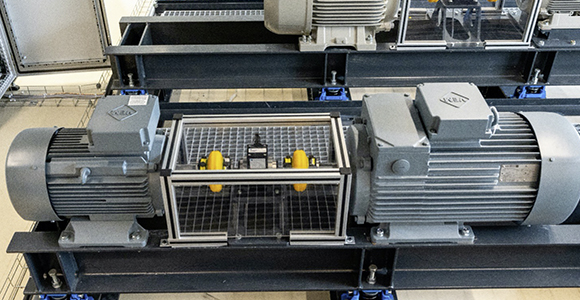

Motor load bench

- Lucas Neulle make: 1 kW squirrel cage induction machine coupled with 1 kW permanent magnet synchronous machine (PMSM)

- 5.5 kW wound rotor induction machine coupled with 5.5 kW permanent magnet synchronous machine (base speed 1500 rpm)

- Magtroltorque sensor with torque display

(™ 310/011 torque transducer with smooth shaft ends, rated torque 50Nm, accuracy < 0.1%, max. torque 100Nm, max. rotational speed 10000min-1)

- Magtroltorque sensor with torque display

- 11 kW wound rotor induction machine coupled with 11 kW permanent magnet synchronous machine (base speed 1500 rpm)

- Magtroltorque sensor with torque display

(™ 311/011 Totque transducer with smooth shaft ends, rated torque 100Nm, accuracy < 0.1%, max. torque 200Nm, max. rotational speed 10000min-1)

- Magtroltorque sensor with torque display

- Two 22 kW squirrel cage induction machine base speed 3000 rpm

Thermal camera

- FLIR T530 w/24° lens 320x240 -20°C-650°C 180° rotating lens platform and a bright 4" LCD

In-house developed SiC based two- and three-level converter

(up to 10 kW and 600 Vdc)

Various electric machines

(PMSM, wound rotor induction machine, squirrel cage induction machine, synchronous reluctance machine)

Realtime controller

(DSpace/Speedgoat etc)

Contact

Ramkrishan Maheshwari

Associate professor

Centre for Industrial Electronics (CIE)

Department of Mechanical and Electrical Engineering

T +45 6550 1686

ramkrishnan@sdu.dk