R2R lab

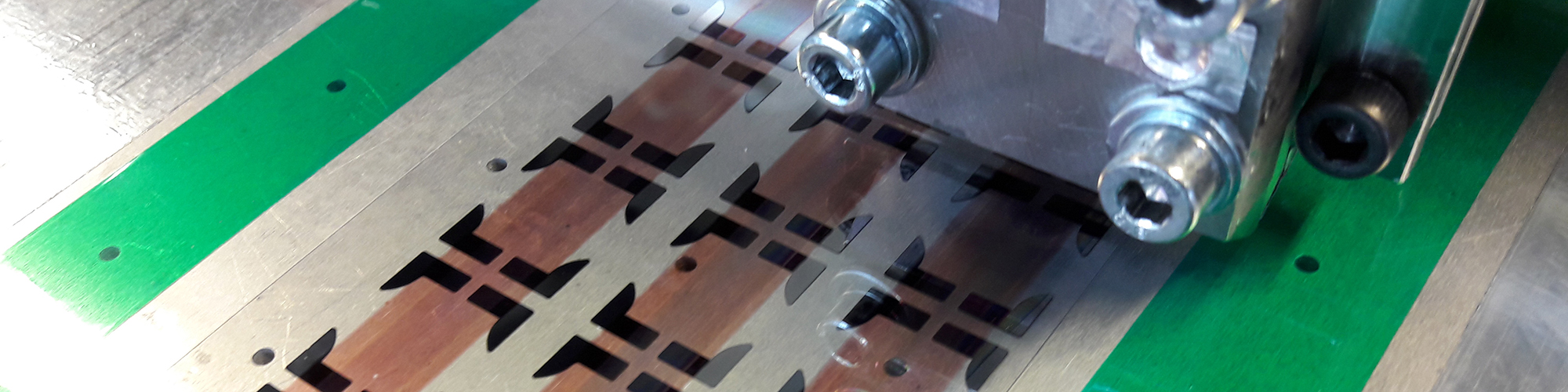

State-of-the-art tools for sheet-to-sheet and roll-to-roll deposition of thin-films on flexible foils at large volumes.

Description

The roll-to-roll laboratory is equipped with state-of-the-art tools for sheet-to-sheet and roll-to-roll deposition of thin-films on flexible foils at large volumes. The tools include amongst other:

- Roll-to-roll vacuum deposition of metals and metal oxide thin-films on flexible foils

- Roll-to-roll slot-die coating of solution processable thin-films on flexible foils

- Sheet-to-sheet slot-die coating of solution processable thin-films

- Roll-to-roll lamination

- Roll-to-sheet nanoimprint lithography

- Tools for spray coating

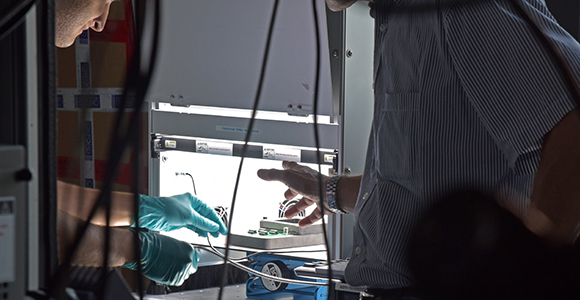

- Device manufacturing tools

We have expertise in coating of various functional (continuous or nanostructured) thin-films from smart materials at large scale. Main application areas include solar cells, light-emitting devices and energy storage applications, but can be extended to other areas where high volume production of thin-films on flexible foils is required.

Services for companies

- Manufacturing of thin functional films at low cost and large scale

- Device design, manufacturing and characterisation

- Characterisation of surfaces and thin-films on flexible foils

Technical specification of equipment

- Roll-to-roll vacuum line with 10 sputter magnetron (2 in pulsed bias mode) targets (web width 305mm)

- Roll-to-roll slot-die coating with web cleaning and drying oven (web width 710mm)

- Roll-to-roll lamination tools

- Sheet-to-sheet slot-die coating lines

- Roll-to-sheet nanoimprint lithography

- Contact angle measurement tool and viscometer

Contact

Morten Madsen

Professor, head of centre

SDU CAPE - Centre for Advanced Photovoltaics and Thin-film Energy Device

Mads Clausen Institute

T: +45 6550 1621

madsen@mci.sdu.dk